"Unmanned systems will become the currency of our state after victory; drones are our calling card. This is the best investment in our economy after the war, to move away from the raw materials market toward a technological-industrial one", - said Vadym Sukharevskyi, Commander of Ukraine's Unmanned Systems Forces, during the first media club event of Technological Forces of Ukraine (TFU), which featured the country's leading defense industry manufacturers.

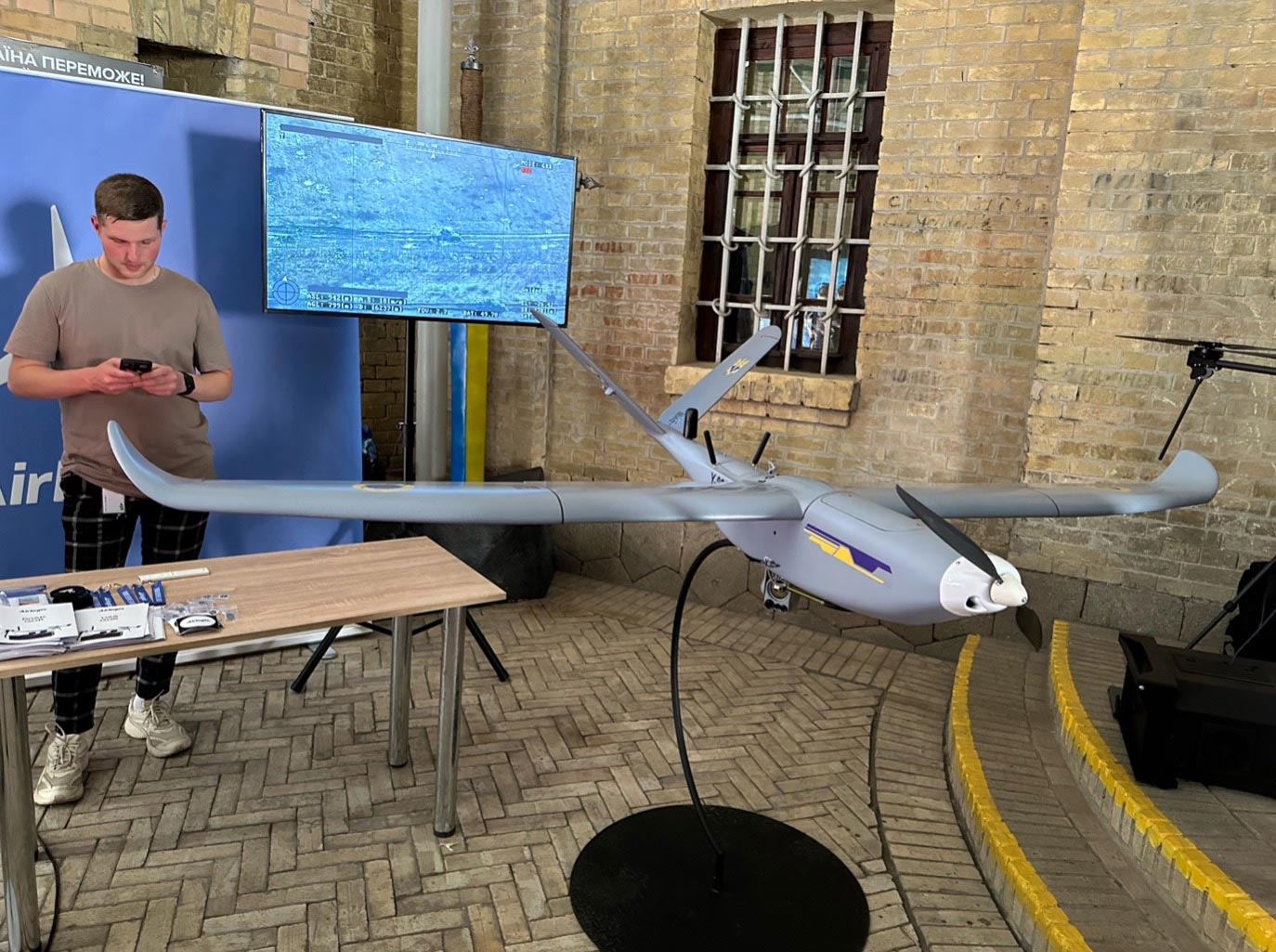

The event took place at the end of August in Kyiv, where several dozen Ukrainian companies showcased their latest developments, mainly drones and other robotic systems.

Among the participants were companies such as "UkrSpecSystems", "Airlogix", "Roboneers", the "Center for Unmanned Systems Research", "Omnitech", "Infozahyst", "Himera", "Vyriy Drones", "Reactive Drones", "FRDM", "Warbirds", "Huless", "Oko Camera", "DeViro", "The Fourth Law", "Atlon Avia", "Quantum Systems", "PG Robotics" and "Taf Drones".

"The adaptability of domestic manufacturers provides the necessary flexibility in terms of the quantity and quality of drones. Almost every day, something changes in this field. Our production can become cyclical, self-contained, and our drones can become mass-produced since they have been tested on the front lines… If we choose the technological development path, then drones are our calling card", - Sukharevskyi emphasized.

At the same time, according to an August 2024 survey of private Ukrainian arms manufacturers, 85% of enterprises stated that they are considering relocating their business abroad or have already done so. The most preferred countries for relocation are the Czech Republic, Poland, and the USA.

The main reasons are the closed export of weapons (70% of respondents), missile strikes (62%), the small volume of government orders (48%), insufficient business profitability, and the lack of state defense contracts (38%), issues with reserving (35%), and pressure from law enforcement agencies (35%).

In addition, 73% of surveyed defense industry manufacturers see no steps from the government to improve conditions for conducting defense business in Ukraine.

One of the key problems mentioned by manufacturers was the closed export of products.

"The profitability of our business is minimal; the state and funds want the cheapest and highest-quality products possible, so conducting business as a business is quite difficult. If we were allowed to export at least 10-15% of our products, it would help the business. We could better plan our production, expand it, and modernize. This would also bring additional foreign currency to Ukraine. But for now, we are not being heard", - one drone manufacturer told OstroV.

President of TFU Vadym Yunik emphasized that arms manufacturers are calling on the authorities to allow "controlled export" of weapons produced by Ukrainian companies.

"Controlled export means that the weapons highly needed by the Ukrainian army will not be sold abroad. However, weapons that are not immediately required by the army can be sold by manufacturers to foreign markets. The army doesn’t always need the full amount of equipment that manufacturers produce. At the same time, they are required to continue R&D, expand production, and respond to front-line demands, which requires additional funding that the state does not provide", - he said.

According to him, in 2024, many enterprises are already in debt to their investors, and opening controlled exports could help alleviate this problem.

Commander of Ukraine's Unmanned Systems Forces, Vadym Sukharevskyi, acknowledged the possibility of export but under certain conditions.

"The main risk is that our equipment could be used against us. Russians could buy our weapons to study and copy them. If we underestimate the risks now and release our weapons abroad, and the enemy copies them, we could lose certain strategies for their use. If these risks are considered, then I see the possibility of export", - he noted.

Another issue raised by Ukrainian manufacturers is the lack of long-term contracts from the state, which makes it difficult for them to plan production.

"For certain categories of weapons, funding is critical for development. For example, a three-month contract wouldn’t be enough to develop long-range drones so that they are effectively implemented and operational. Therefore, it’s crucial for the state to learn how to fund the latest developments in Ukraine because we are producing products that the rest of the world might not be able to replicate", - explained Kateryna Mykhalko, Executive Director of the Technological Forces of Ukraine.

In addition, the production capacities of enterprises remain idle until a contract is signed and prepayment is received. For example, according to a TFU survey, 38% of companies indicated that more than half of their production capacities are currently idle. Only 35% of the surveyed enterprises reported that their capacities are fully utilized today.

To better understand the issues faced by manufacturers, OstroV spoke with Kostiantyn Minakov, head of the company "OmniTech Defense".

About the company and the system

The company "OmniTech Defense", specializing in the development of unmanned aerial systems, was founded in 2023. In the same year, it conducted tests of the Skytech unmanned complex, which is now supplied to the Armed Forces of Ukraine (AFU).

It was with the Skytech systems that the russian heavy flamethrower system Solntsepek was hit a few months ago. In addition, there have been hundreds of hits on enemy equipment: tanks, infantry fighting vehicles, armored personnel carriers, artillery installations, and transport trucks.

The system includes UAVs (seven- and ten-inch drones), a ground control station, a relay, servicing tools, and an initiation board for the warhead.

"Today, we supply these systems directly to brigades, foundations, and under government contracts. They are used daily on the battlefield. Thousands of drones have already been delivered and deployed", - said the head of the company Kostiantyn Minakov.

He emphasizes that Skytech systems are manufactured in Ukraine and are continuously adapted to meet combat needs.

"There are components that we have developed ourselves, and there are those we import from other countries. For example, the initiation board is our own development. To use any drone today, there needs to be an initiation board that ensures the detonation of the warhead. It's very important that it works 100%, with no false triggers. That's why there's a complex approval and testing procedure. Our initiation board, UAV, and the entire system, approved for use by the Ministry of Defense, have the corresponding NATO coding", - he told OstroV.

Minakov notes that all of the company’s developments undergo combat testing before entering mass production. According to him, it is crucial to collaborate with the military and receive their feedback.

"When a problem arises, we make adjustments and move forward. There is a need, so we create a new modification. It’s a constant process, continuously meeting the demands of our military as they arise on the battlefield, without delays", - said the company’s head.

He emphasized that if you look at any FPV drones, they may all look almost the same externally, but the real differences are in the components and technologies used and how they adapt to changes at the front.

"All our developments are based on combat experience. We don't have any projects that were made in isolation. For example, here we have our video communication module, which consists of a video transmitter (located directly on the drone) and a video receiver (located in the ground station or relay). I must emphasize that this is our own development. All the frequencies in use today are known, and the enemy can adapt to them. But when you have non-standard frequencies, the enemy can't adapt as quickly.

At this point, we've completed the first iteration, and the second one is already in development. The second version will have smaller dimensions and a lower final cost, specifically for mass production. The first version is currently being tested in combat conditions. Until we get feedback on its effectiveness in combat, we won’t launch it into mass production", - he explained.

"As for the operation of the ground control station, our concept is based on a structure of external modules. The key feature is the lightweight design and modularity. You don't need to carry a massive mast or a large amount of equipment to the position. You have a case located in a dugout, and through cables, a direct connection is made with the elements of the ground station placed above.

There’s a module for communication management with the relay, a module for direct communication between the ground station and the drone, and video communication modules either through the relay or directly with the drone. The crew only uses what’s needed at any given moment. A relay on another drone is lifted into the air, the signal is transmitted from the drone to the relay, from the relay to the ground station module, and via cable from the ground station into the dugout, where it goes to a monitor or goggles", - explains Kostiantyn Minakov, emphasizing that this is an entirely Ukrainian development.

According to him, this setup allows them to negate the effects of terrain and operate over long distances.

The company also uses its own modular guidance system.

"In our UAVs, we use a guidance system developed in collaboration with our partners. Its key feature is modularity, meaning you can take any drone and add this guidance system to it. Your task is simply to connect it to the UAV, and it will enable the drone to operate autonomously. The operator sees the video, targets are locked, and the drone continues flying in autonomous mode without operator control. This makes it resistant to enemy electronic warfare (EW). This is gradually becoming mainstream, and manufacturers are adopting these systems. There are many guidance systems that are directly integrated into the drone, and you can't use the drone in any other way. In our case, you can take any FPV drone and add our guidance system", - he says.

"OmniTech Defense" also presents a spotlight for FPV drones that can be used instead of a thermal imaging camera.

"An infrared spotlight at the UAV’s operating altitude, which is 50-100 meters, will provide visibility similar to a thermal camera. But our spotlight costs around 1,000 UAH, whereas a thermal camera costs 20,000 UAH. This is our own development, actively used on the front. Of course, it's not a complete replacement for a thermal camera, but in a way, it offers an intermediate level", - explains Kostiantyn Minakov.

Challenges and issues

Today, the company "OmniTech Defense" has the capacity to produce over 3,000 drones per month with the ability to scale.

"But in reality, we are currently producing about a thousand units per month. The main problem is the lack of a long-term production plan, which is tied to the absence of long-term government contracts. In other words, you get a contract, you fulfill it, and then you don’t know if there will be a new one tomorrow or not. This results in constant searching and an inability to properly plan", - says Minakov.

He emphasizes that manufacturers need contracts for one or two years, which would allow production to understand how many systems need to be made.

"Based on this, you can easily plan the entire production process cycle, ensuring quick and proper delivery. There is a specific process: if we're talking about purchasing components, it takes about two to three months from procurement to production. This also affects the cost. When you know, for example, that you're making three thousand drones per month, you plan procurement from that perspective. Planning is one of the key issues that needs to be resolved", - he emphasizes.

It is crucial to develop our own systems that allow us to stay one step ahead of the enemy, making it difficult for them to adapt. However, sometimes these systems are more expensive than, for instance, using Chinese components, notes the head of "OmniTech Defense".

"For example, we can buy a video transmitter from China, but the enemy can buy jammers there that will disrupt the frequencies of the video transmitter. To prevent this, we need to produce certain critical components ourselves", - says Kostiantyn.

According to him, most components can now be produced locally in Ukraine.

"For example, there are Ukrainian-made frames, flight controllers, control systems, and engines. Video communication systems are not yet in mass production, but we will have our first mass-produced analog video communication system. Batteries are made in Ukraine, but the modules they consist of are bought abroad, not just in China. There is no mass production of cameras in Ukraine yet, but there is progress in that direction. We have a thermal imaging module for FPV drones, but it’s also Chinese. For instance, we have a Ukrainian manufacturer Glaz Camera that makes thermal imaging modules, but they haven't yet reached FPV drones, as their production is focused on larger UAVs", - he explained in a comment to OstroV.

At the same time, there is the question of the cost of products when they are made using Ukrainian, rather than Chinese, components.

"When we talk about Chinese manufacturing, they have huge potential and order volumes, allowing them to make cheaper components. Therefore, the question always arises: should we buy a more expensive Ukrainian drone frame or a cheaper, similarly high-quality Chinese one? This is why I believe the state's role is to stimulate the development of this industry, but not solely focusing on the price factor.

For example, what is the issue with a tender for the procurement of UAVs? When you hold a tender to buy certain drones, they may all meet the technical specifications, and theoretically, they can all fly 10 kilometers (whether with cheaper or more expensive components). But at the front line, they will perform completely differently. One might be discarded and not used, while the other will deliver tangible results. If the state's main concern is price alone, we won't be able to offer a product with higher-quality components. In the end, our price will be higher, and we won't win the tender", - he explains.

In his opinion, the brigades using the drones should independently form their requests.

"In reality, there is progress in this direction. We've had discussions with the Ministry of Defense, and they see this possibility. But it's a gradual process because there are several entities (the Defense Procurement Agency, State Special Communications Service, and so on) that handle the bulk of the procurement. In my view, we need to completely change the procurement philosophy — instead of centralized procurement, the priority should be on direct interaction between the end user and the manufacturer.

In other words, the state should create a general catalog of approved products, determine the price of each product, and pass this catalog from manufacturers to specific military units. These units would then communicate and decide which product to purchase. This would radically change the situation", - he noted.

Regarding the export of products, according to Kostiantyn Minakov, head of the "OmniTech Defense", Ukrainian companies could already be selling their products abroad today.

"The complete system is sufficient to be marketed internationally. We are currently planning to undergo certification procedures to meet all NATO requirements so that different countries can purchase our products, primarily for the Defense Forces of Ukraine", - he said.

Moreover, after the war, Ukrainian manufacturers will not be left without work—they can export their products abroad.

"It's all about technology. If we move away from simply assembling drones from ready-made components to exclusive in-house developments using modern technology, such products could be exported abroad", - he believes.

By Vladyslav Bulatchik, OstroV